Valverbe produces its tea bags following a supply chain logic that goes from seed to finished product.

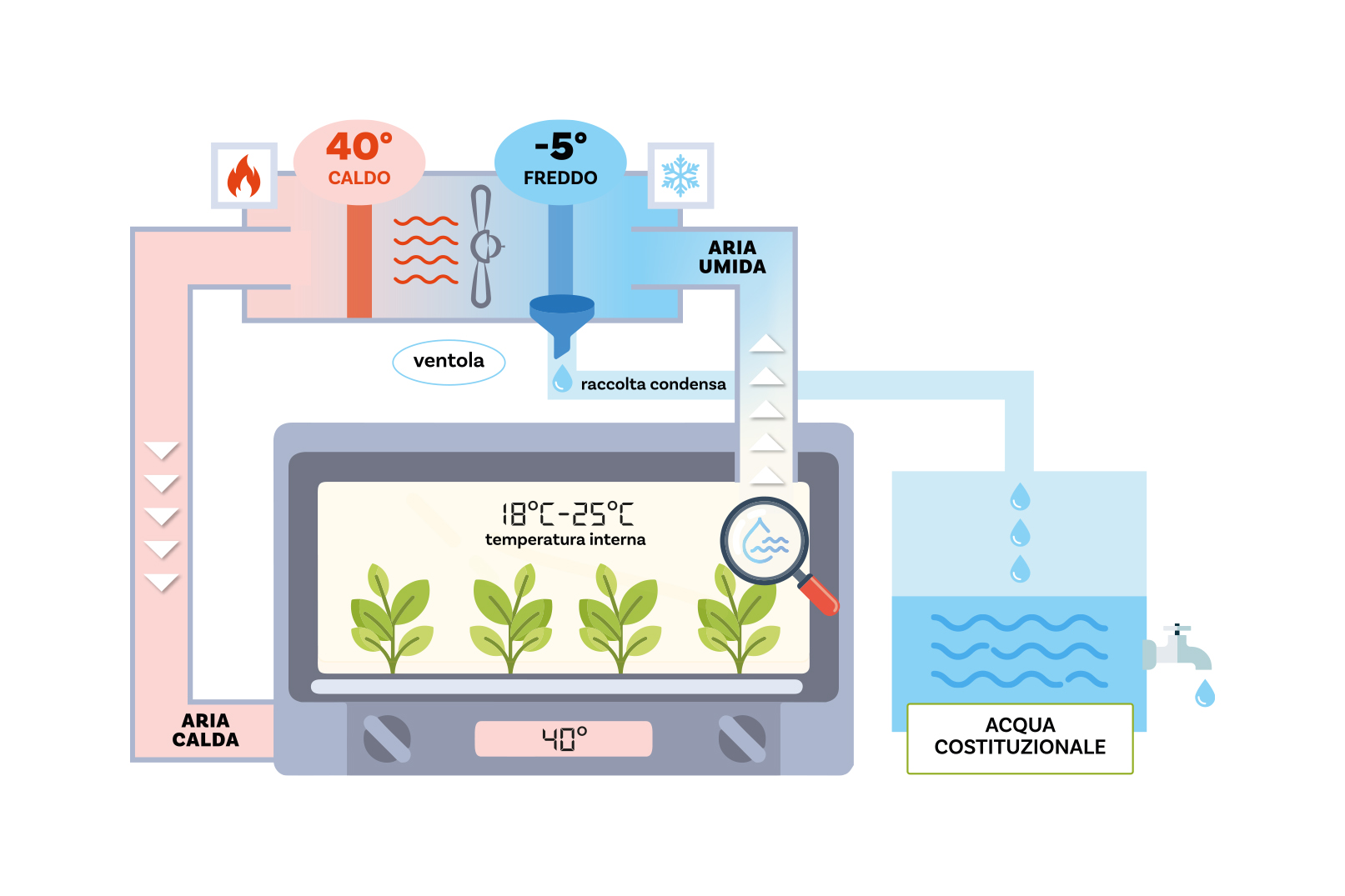

One of the most important stages of this process involves drying the herbs, which depends on multiple factors related to conservation, aroma, and the active ingredient content of the final product.

Drying involves significant chemical and physical changes to the plant tissue, and the dehydration process helps stabilize them by stopping the enzymatic degradation processes that affect the plant immediately after cutting.

Our cooperative has invested heavily in this phase, purchasing a unique cold-drying system in Italy – using CFT® technology – which, unlike the traditional hot-drying process, preserves the cell membrane intact, and with it, all the properties of the plant.

Start of Drying

The cell membrane is intact